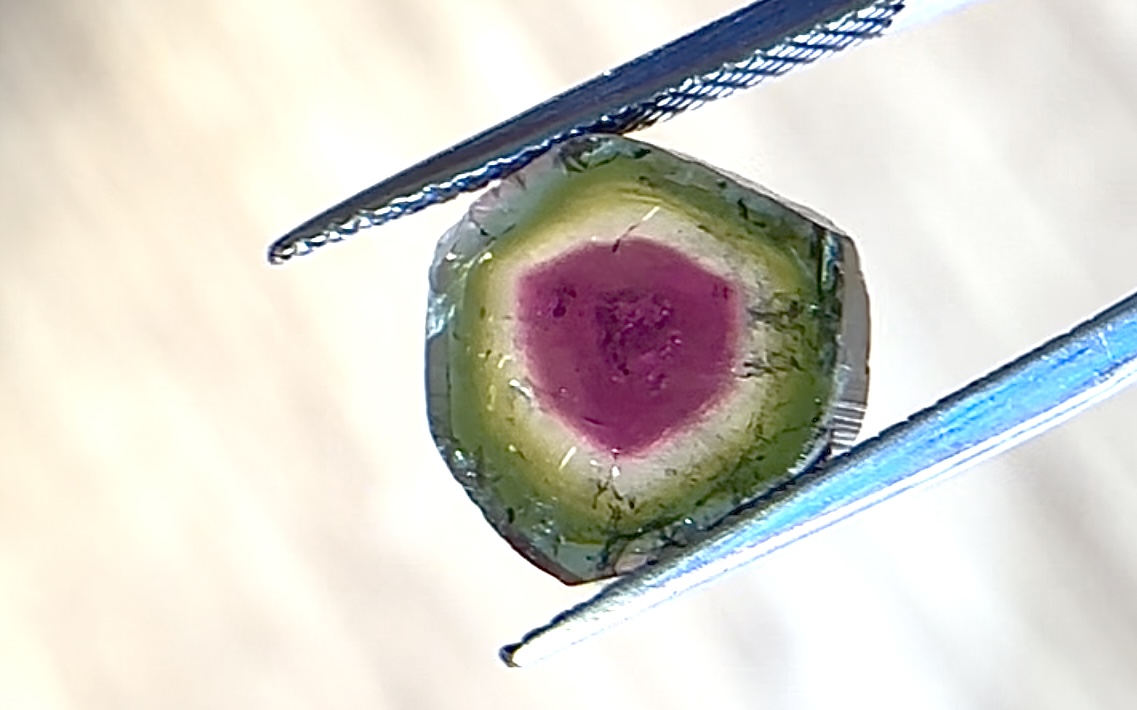

Watermelon Tourmaline

Watermelon Tourmaline Watermelon tourmaline is a captivating gemstone celebrated for its remarkable blend of colours and unique beauty. Belonging to

choose a stone…

choose a setting…

choose a metal…

choose a finish…

…choose ring

21 Meeting House Lane

Brighton East Sussex

BN1 1HB

1273 773 544

21 Meeting House Lane

Brighton

East Sussex

BN1 1HB

Categories:

If you saw a rough diamond on the floor you would probably not even stop to pick it up. The romantic myth that diamonds glisten against the dark rough rocks in which they are found is sadly not true. A diamond in the rough looks more like a piece of old glass bottle you may see washed up on a beach. Only around 25% of diamonds mined are without at least some faint colour. Another 25% are a light shade of yellowy brown. These stones are deemed 'off-colour'. The other half of all diamonds found are so deeply coloured that they are not high enough quality or value to be used in jewellery. None of these diamonds go to waste though. They have industrial uses like drill bits. Diamond dust is even put to use for cutting other diamonds!

Only around 25% of diamonds mined are without at least some faint colour. Another 25% are a light shade of yellowy brown. These stones are deemed 'off-colour'. The other half of all diamonds found are so deeply coloured that they are not high enough quality or value to be used in jewellery. None of these diamonds go to waste though. They have industrial uses like drill bits. Diamond dust is even put to use for cutting other diamonds!

Rough diamonds have a 'window' polished into them so the stone can viewed in detail & a map of how to cut the stone to yield the greatest value is marked. The person marking the stone must consider where the location of the diamond's inclusions are & will mark the stone for cutting in a way that will make the most of the stones potential value. The marker will also decide the direction of the 'grain' or 'cleavage' of the diamond because there are four possible directions.

Next the diamond is 'cleaved. In this stage a groove is cut along a line showing where the stone is to be cleaved. The cleaver then inserts a steel wedge shaped tool into the groove and strikes the wedge firmly with a mallet to split the diamond along its cleavage. This is a very important stage because if things do not go according to plan the diamond can actually shatter.

The next stage is sawing the diamond using either a very thin phosphor bronze disc or a laser. If the saw is used it is coated on the rim diamond dust (I told you nothing goes to waste!). The alternative to the metal saw is Laser Sawing. This is incredibly accurate & has become more & more popular in recent years.

After the sawing comes 'bruting'. The stone is placed in the chuck of a lathe and as it spins, a second diamond is held against it. This slowly smoothes & rounds the diamond into a cone shape. The next stage is when a diamond really starts to look like a diamond. This is when the facets are added. The most popular cut of diamond these days is the round, brilliant cut. This stunning cut of diamond, that sits on many a ring finger, has 58 individual facets that are all added at this stage. After the facets have been polished the stone is heated in acid to remove any oily residues.

The next stage is when a diamond really starts to look like a diamond. This is when the facets are added. The most popular cut of diamond these days is the round, brilliant cut. This stunning cut of diamond, that sits on many a ring finger, has 58 individual facets that are all added at this stage. After the facets have been polished the stone is heated in acid to remove any oily residues.

Watermelon Tourmaline Watermelon tourmaline is a captivating gemstone celebrated for its remarkable blend of colours and unique beauty. Belonging to

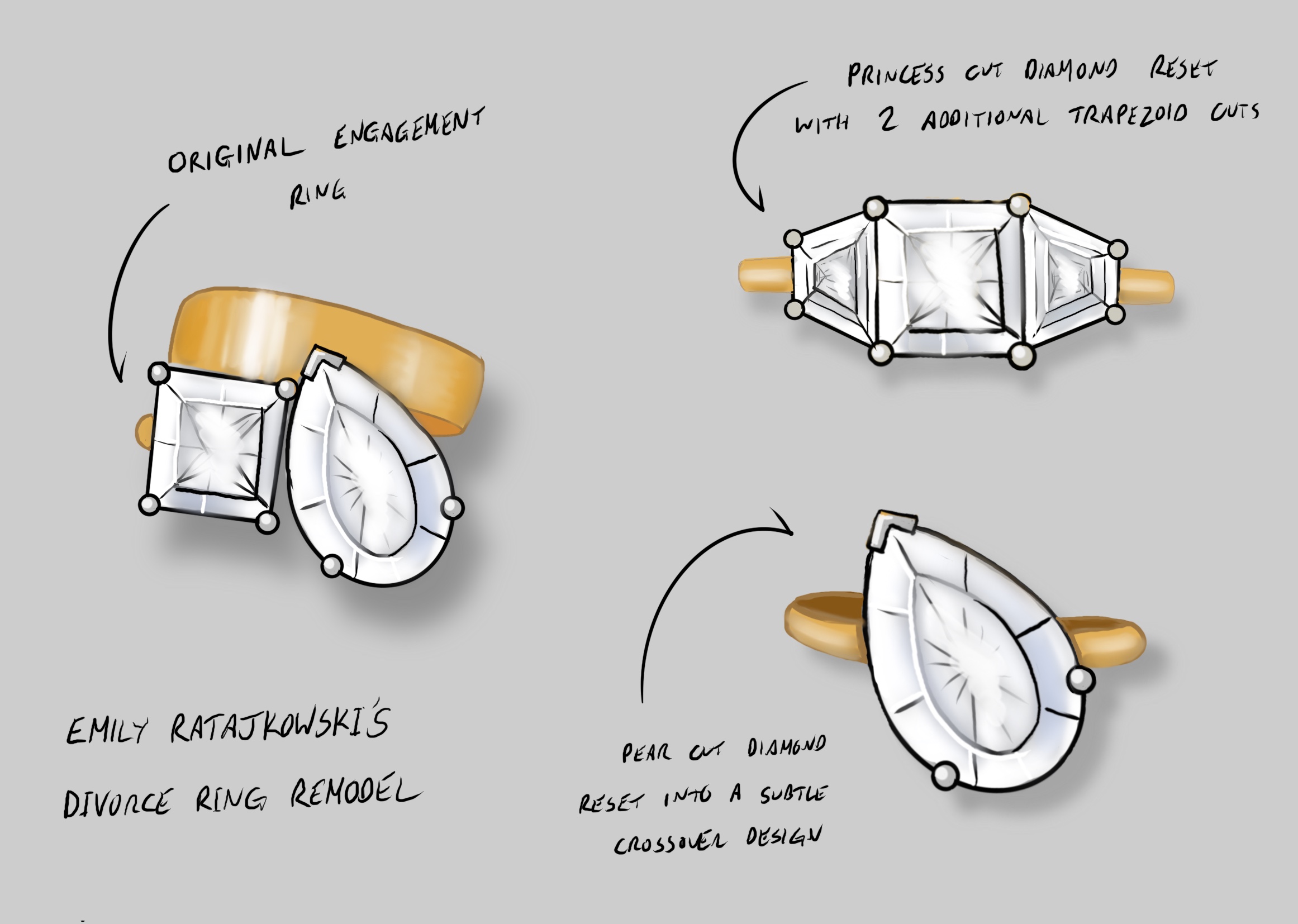

Transforming Pain into Beauty: The Rise of Divorce Rings In jewellery a Diamond is usually a symbol of love whether

Which finger is the engagement ring worn on? In the UK, as with many other Western countries, an engagement ring

Tel: +44 (0) 1273 773 544

Email: ringdesign@hotmail.co.uk

21 Meeting House Lane

Brighton

East Sussex

BN1 1HB

Open 7 days a week

Mon-Sat: 10:30am – 5pm

Sun: 11am – 4:30pm